Technical specifications series AS

| Type* | Capacity litres | Width cm | Weight kg |

|---|---|---|---|

| AS 1500 | 900 | 150 | 360 |

| AS 1750 | 1100 | 175 | 385 |

| AS 2000 | 1300 | 200 | 410 |

* Standard : front attachment

– Standardly equipped with hydraulic hoses and ½” male BSP couplings

– Necessary hydraulic power : 30 l./min. – 180 bar (max. 60 l./min. – 200 bar)

Options series AS

– Three-point linkage

– Two-fold control valve

– Pressure relief valve

– All common quick attachments

Technical specifications series ASM

| Type* | Capacity litres | Width cm | Weight kg |

|---|---|---|---|

| ASM 1500 | 1100 | 150 | 485 |

| ASM 1750 | 1300 | 175 | 530 |

| ASM 2000 | 1500 | 200 | 575 |

| ASM 2500 | 2400 | 250 | 775 |

* Standard : front attachment

– Standardly equipped with hydraulic hoses and ½” male BSP couplings

– Necessary hydraulic power : 30 l./min. – 180 bar (max. 60 l./min. – 200 bar)

Options series AS

– Three-point linkage

– Two-fold control valve

– Pressure relief valve

– Adjustable bottom plate

– All common quick attachments

AP Cubicle bedders

Suitable for various types of bedding material

Constant spreading pattern

Self-loading

Suitable for both front and rear attachment

Very maintenance-friendly

Solid construction = long service life

Specially developed conveyor belt

AP Cubicle bedders are multifunctional spreaders that can process multiple products at a constant spreading pattern. The specially developed conveyor belt is equipped with a v-belt that prevents misalignment. Due to the two raised sides on the conveyor belt little or no bedding material can get under / between the belt.

Because the cubicle bedders are equipped with a mounting frame they are suitable for both front and rear attachment.

AS series

The type AS is a simple yet solid, self-loading machine that can process multiple products at a constant spreading pattern. A large conveying auger ensures a forced output to both sides of the machine. Thanks to this forced output it is possible to spread the bedding material (mentioned below) over a large width.

Because the machine is equipped with a mounting frame the AS is suitable for both front and rear attachment. When used in the front of a machine the bedder can be provided with all common quick attachments (boltable) for front / wheel loader or telescopic handler. Only one double functioning valve is required.

When used behind the tractor, a 3-point linkage will be mounted. In this case the tractor must be supplied with two double functioning valves. If it is equipped with only one double or single functioning valve a 2-fold control valve can be optionally mounted on the cubicle bedder.

The AS is suitable for the spreading of:

Sawdust

Dried manure

Shortly chopped straw (< 3 cm)

Shreds

Wood chips

Downsized materials

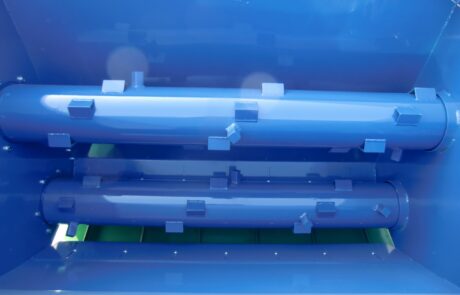

ASM series

Type ASM is a cubicle bedder for intensive use that can process nearly any type of bedding material by means of two powerful agitator shafts. Due to the special shape of the bucket the loading of the material is easy. The ASM can also be used to process corn and/or mixed feed from a feed mixer.

Because the machine is equipped with a mounting frame the ASM is suitable for both front and rear attachment. For use with a front / wheel loader or telescopic handler the bedder can be provided with all common quick attachments (boltable). Only one double functioning valve is then required.

If the bedder is used behind a tractor a 3-point linkage will be mounted. In this case the tractor must be supplied with two double functioning valves. If it is equipped with only one double or single functioning valve a 2-fold control valve can be optionally mounted on the cubicle bedder.

All cubicle bedders, type ASM, are delivered with scrapers (separately). By mounting these scrapers on the dispensing shaft the the separately supplied scrapers the volume of material on the conveyor belt can be increased.

The ASM is suitable for the spreading of:

Sawdust

Chopped straw

A mixture of straw/lime/water

Horse manure

Paprika and tomato stems

Compost & digestate

Ikke nogle videoer, endnu.