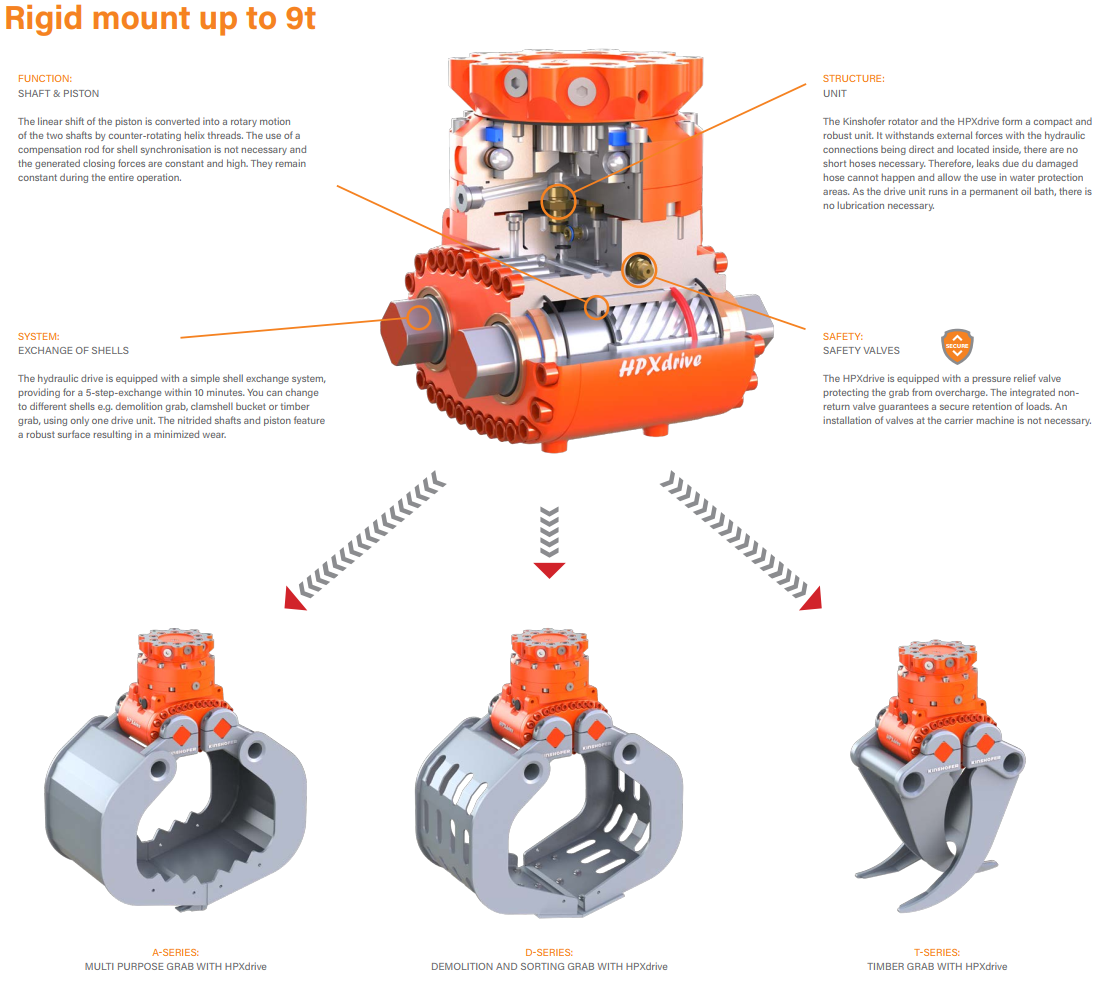

Hydraulic drive unit for rigid mount up to 9t

| Type | Tonnage | Opening | Closing force |

| A04HPX | 2 – 4t | 1043 mm | 18 kN |

| D04HPX | 2 – 4t | 1045 mm | 18 kN |

| A06HPX | 4 – 6t | 1344 mm | 18 kN |

| D06HPX | 4 – 6t | 1350 mm | 18 kN |

| T06HPX | 4 – 6t | 1210 mm | 17 kN |

| A09HPX | 6 – 9t | 1545 mm | 15,5 kN |

| D09HPX | 6 – 9t | 1545 mm | 15,5 kN |

| T09HPX | 6 – 9t | 1210 mm | 17,5 kN |

The information about the closing force refers to the max. working pressure of 250 bar.

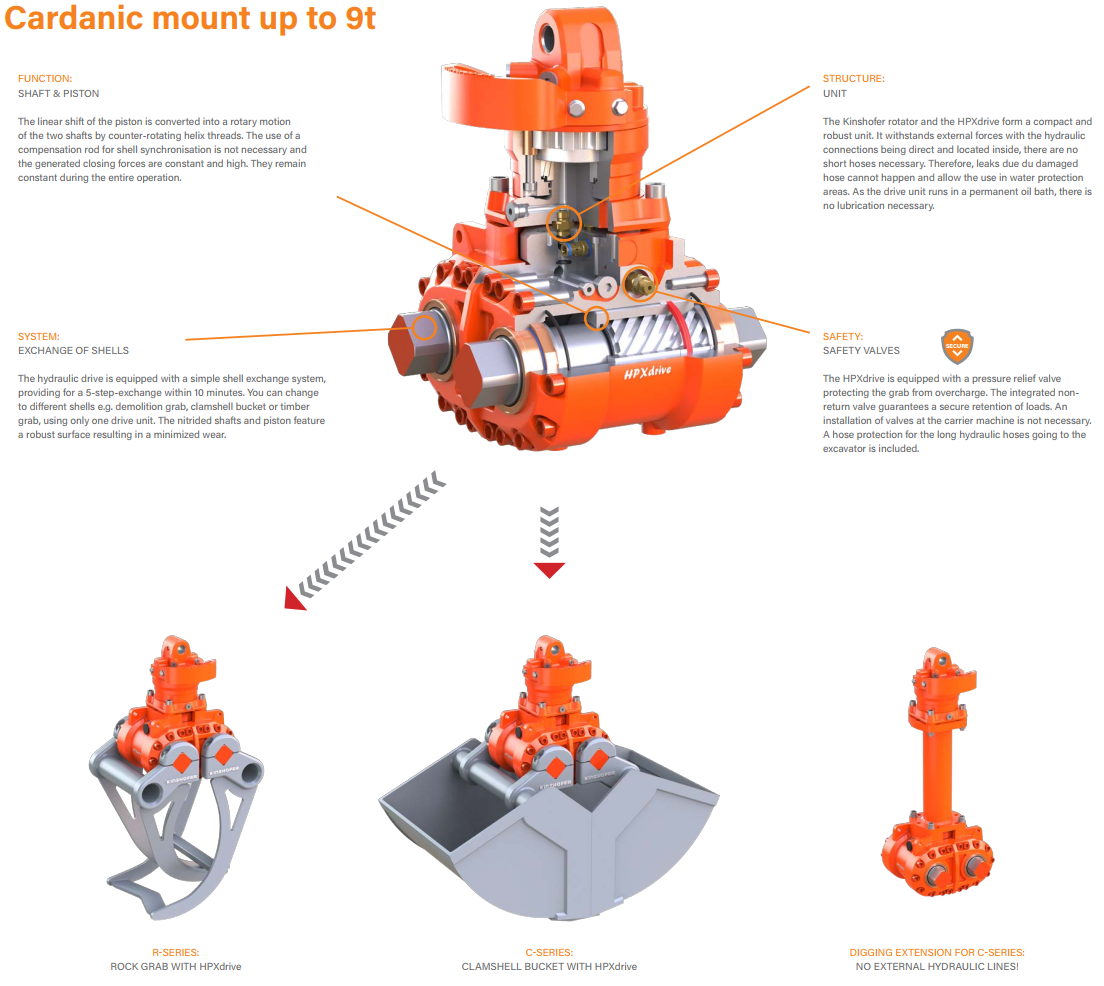

Hydraulic drive unit for cardanic mount up to 9t

| Type | Tonnage | Opening | Closing force |

| C05HPX | 3 – 6t | 1110 mm | 25 kN |

| C08HPX | 6 – 9t | 1250 mm | 22 kN |

| R05HPX | 3 – 6t | 1210 mm | 18 kN |

| R08HPX | 6 – 9t | 1210 mm | 18 kN |

The information about the closing force refers to the max. working pressure of 250 bar.

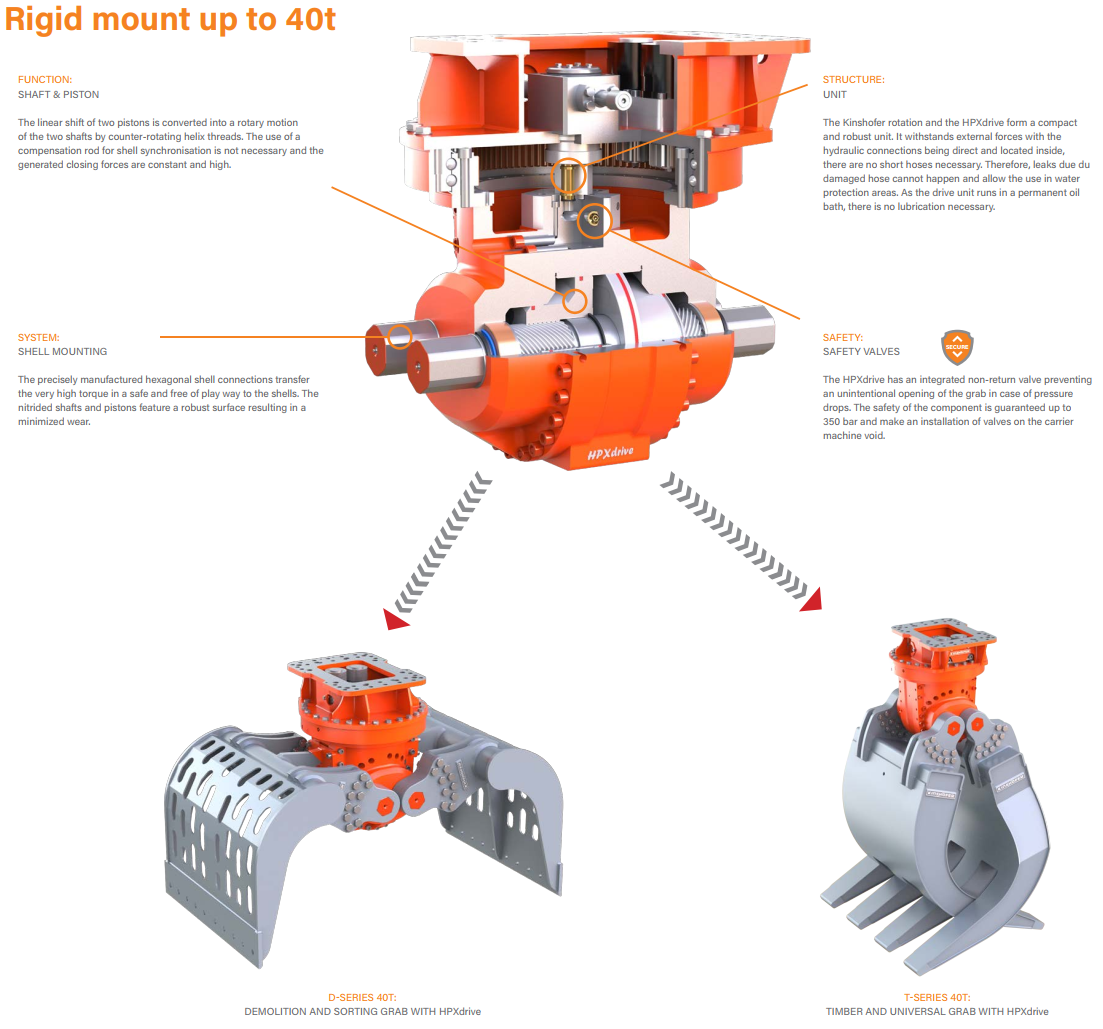

Hydraulic drive unit for rigid mount up to 40t

| Type | Tonnage | Opening | Closing force |

| D27HPX | 20 – 27t | 2000 mm | 79 kN |

| D32HPX | 25 – 32t | 2150 mm | 72 kN |

| D37HPX | 32 – 37t | 2250 mm | 69 kN |

| T40HPX 4/3 | 25 – 40t | 2900 mm | 43 kN |

The information about the closing force refers to the max. working pressure of 350 bar.

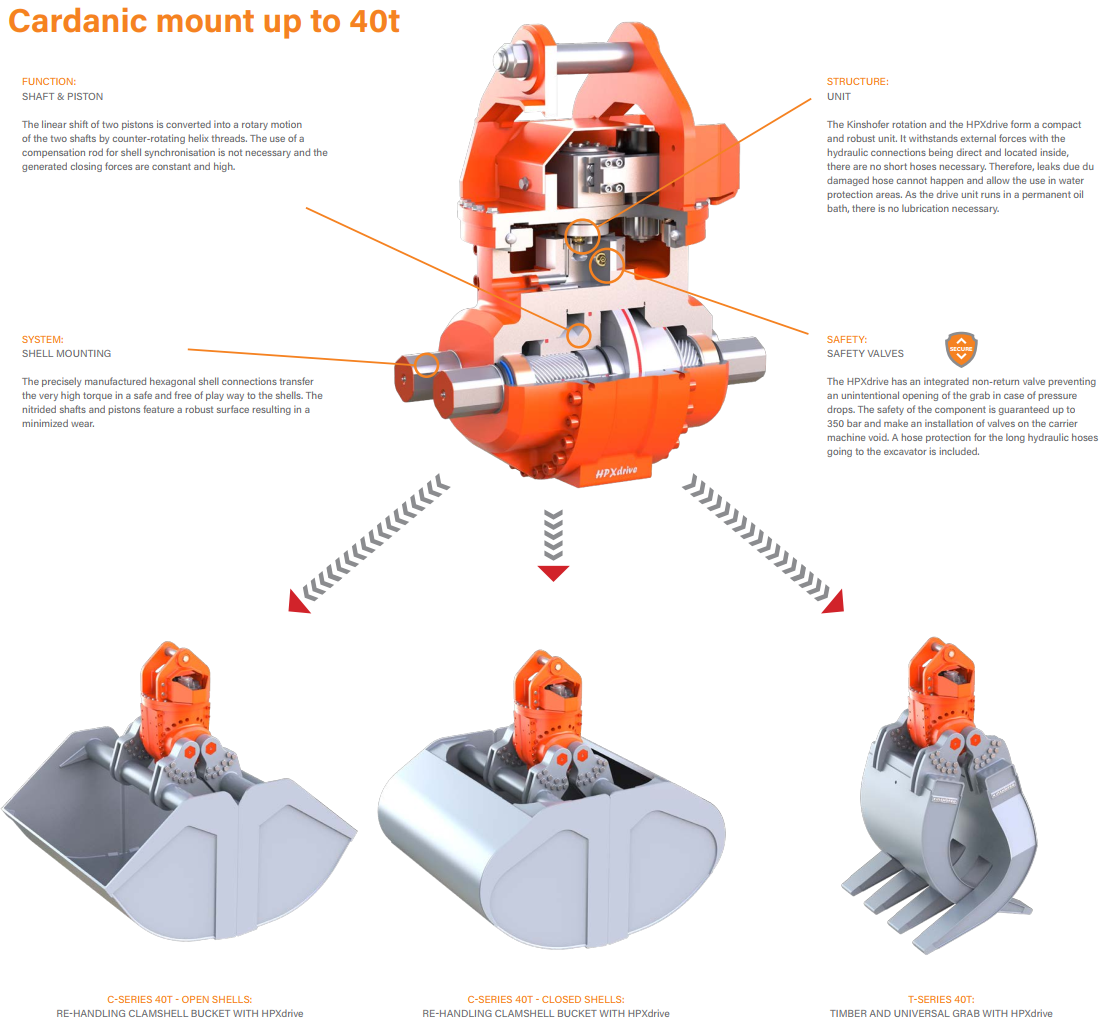

Hydraulic drive unit for cardanic mount up to 40t

| Types | Tonnage | Volume | Closing force |

| C40HPX | 20 – 40t | 1250 – 5000 l | 55 – 69 kN |

| C40HPX-C | 20 – 40t | 2250 – 5000 l | 55 – 63 kN |

| T40HPX | 20 – 40t | 1.0 – 2.5 m2 | 24 -41 kN |

| T40HPX 4/3 | 25 – 40t | 1.14 m2 | 43 kN |

The information about the closing force refers to the max. working pressure of 350 bar.

Functional exchange, depending on demands!

During times of growing costs and environmental awareness, efficient working is getting more and more important. The HPXdrive stands out thanks to its extended lifetime compared to a conventional cylinder-driven grab. Not only the maintenance downtimes are reduced but also the operational expenses. The integrated shell exchange system and the different available shell options provide for a higher flexibility on the one hand, and lower the asset cost for additional attachments on the other hand.

CUSTOMER BENEFITS:

FLEXIBLE OPERATION

Fast and uncomplicated response to requirements to be more competitive.

LOW MAINTENANCE

No greasing points at the HPXdrive that need to be lubricated on a daily basis, saving time and maintenance costs.

LESS WEAR

The compact and extremely robust design without hydraulic cylinders or short hoses lower the risk of damages.

HIGHER EFFICIENCY

More powerful working thanks to constant closing forces during the entire gripping performance. The tasks can thus be finished faster and the wear is kept to a minimum.

Compact design

The compact and very robust design of the HPXdrive unit has no greasing points and combined with a KINSHOFER directly mounted rotator, there are no short connecting hoses required anymore (internal hydraulic connections).

HPXdrive up to 40t

HPXdrive under water

Clamshell Bucket with HPXdrive